Introduce

ASIC Service Info

Development Process

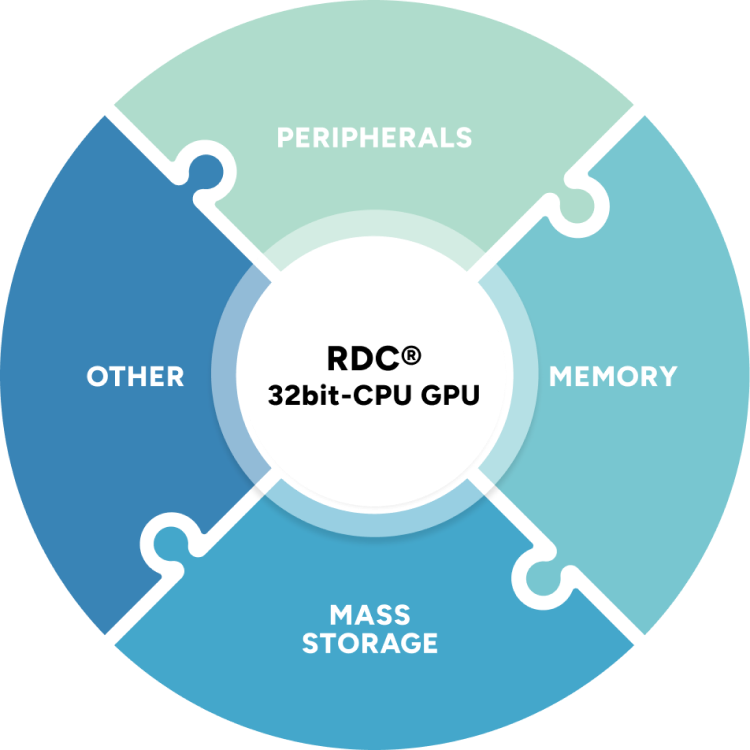

RDC® ASIC provides comprehensive services and industry application solutions. First, in design services and mass production, from design, manufacturing to backend packaging and testing, RDC® offers customized service solutions. In terms of applications, depending on different industry needs such as embedded applications, industrial automation, cloud IoT industries, etc., RDC® provides hardware specification design recommendations and seeks hardware-software compatibility from a system perspective, offering customers complete hardware specification configuration and design. For functional verification, RDC® provides different verification methodologies in stages to enhance verification completeness. For customization, from CPU to various peripheral devices, from standard interfaces to special specifications, rich functional offerings help customers design diverse application chips. In terms of process technology, ranging from mature to advanced processes, RDC® selects the most suitable process based on customer system requirements and cost-effectiveness to achieve optimal performance. RDC® provides flexible and comprehensive solutions to help customers strengthen their products and consolidate their market position.

RDC®'s customized R&D process builds the most cost-effective custom chips for customers from a system perspective.

RDC®'s customized R&D process builds the most cost-effective custom chips for customers from a system perspective.

RDC ASIC Service Flow

During the specification customization phase, we discuss product applications and specification requirements with customers and provide design suggestions that meet needs and costs. In the chip design phase, we use FPGA test boards to simulate and evaluate performance for system optimization. In the physical layer design phase, we utilize computer-aided software to evaluate and optimize power consumption and performance. In the functional verification phase, staged verification methods are provided to enhance verification completeness and reduce verification response time to shorten R&D timeline. Finally, in the chip mass production phase (including wafer production services to chip packaging and testing) we help customers optimize mass production procedures and reduce mass production risks. RDC® engages with customers at each stage of the process, listens to customer feedback, and provides solutions that best meet cost and performance requirements.

Software technical support

Regarding technical support for software, RDC® offers software development kits for the development of RDC® drivers, BIOS, system imaging, sample codes, and programming guides, and even easy-to-use embedded application systems that allows developers to rapidly compile programs regardless of their preferred OS, such as Windows-based OS or open-source Linux-based OS.

Hardware technical support

Regarding technical support for hardware, RDC® provides support in 2 major aspects, specifically circuit design and, more importantly, production. For the former, RDC® provides evaluation board circuit design reference drawings and layout files to assist developers in re-checking their circuit board designs and provides revision suggestions. For the latter, RDC® offers comprehensive service of production and mass production tools to enhance clients’ production capabilities and production reliability.

For product implementation and development

For product implementation and development, and in response to the increasing complexity of software and hardware designs, RDC® offers the RDC® Tool Chain, which helps clients easily develop application systems, and the RDC® JTAG Debugger. This debugging tool not only features basic debugging functions, but clients can also independently use the JTAG Debugger to control processors. The JTAG Debugger assists clients in rapidly completing debugging procedures and reducing development process of new products.